Deformed steel bars, also known as reinforcing bars or rebars, are a critical component in concrete construction. They have surface deformations in the form of ribs, lugs, or indentations to enhance their bonding with concrete. These deformations improve the mechanical properties and performance of reinforced concrete structures.

Types:

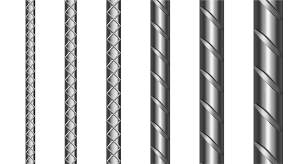

- Hot-Rolled Deformed Bars (HRB): These bars also known as thermo-mechanically treated bars are manufactured by hot-rolling, where steel billets are heated and passed through a series of rollers to create the desired deformations. Hot-rolled deformed bars are available in various grades and sizes.

- Cold-Worked Deformed Bars (CRB): Cold-worked bars, also known as high-strength deformed bars or cold-drawn bars, are produced by stretching or drawing hot-rolled steel bars through a series of dies to create the deformations. They have a smoother surface compared to hot-rolled bars.

Characteristics:

- Deformed steel bars have a pattern of deformations on their surface, which can be in the form of ribs, lugs, or other irregular shapes. These deformations create a mechanical bond with the surrounding concrete, preventing slippage and improving load transfer between the steel and concrete.

- Deformed bars have high tensile strength, which is essential for reinforcing concrete structures. The deformations enhance the bond between the rebar and the concrete, enabling the concrete to carry tensile forces effectively.

- Deformed steel bars are designed to have good ductility, allowing them to deform without sudden failure under high stress. This ductility is crucial in applications where the structure needs to absorb energy during stress events.

- Deformed bars are manufactured according to international and national standards, ensuring quality and consistency in their properties and dimensions. Common standards include ASTM A615 (USA), BS 4449 (UK), and IS 1786 (India).

Benefits:

- The deformations on the surface of deformed steel bars significantly improve the bond between the rebar and concrete. This enhances the structural integrity of concrete structures, especially under tension.

- Deformed bars offer a higher load-carrying capacity compared to plain (smooth) bars. This is crucial in applications where the concrete needs to bear heavy loads and resist stresses.

- Deformed bars are ductile, providing resilience and flexibility to concrete structures, making them better equipped to handle dynamic loads and seismic events without abrupt failure.

- Deformed bars contribute to the stability and safety of structures, making them suitable for use in a wide range of applications, including buildings, bridges, roads, and other infrastructure.

- Deformed bars are manufactured in accordance with industry standards, ensuring quality, consistency, and compliance with engineering requirements.